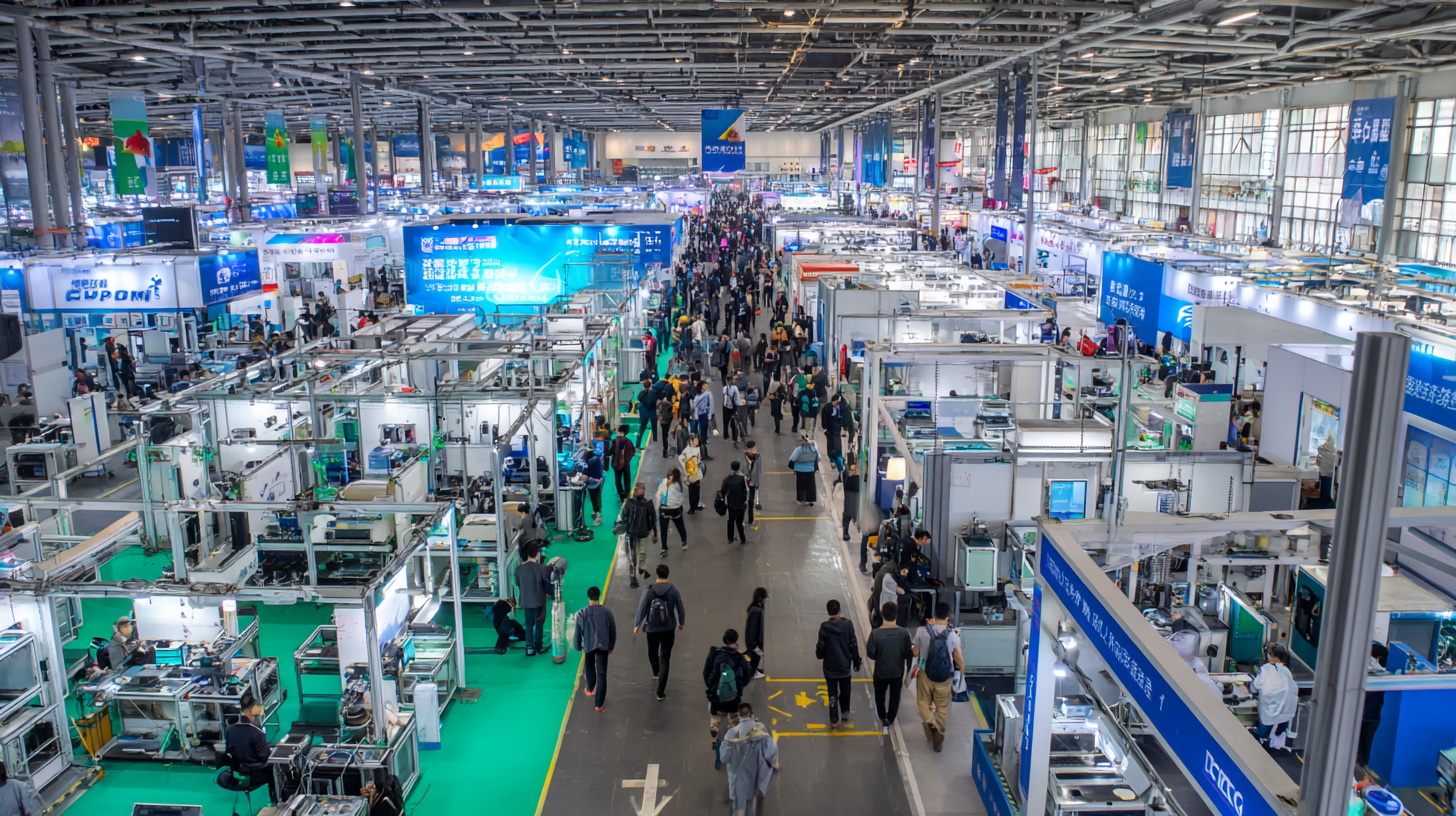

Emerging Trends in PCBA Manufacturing Highlighted at 2025 China Import and Export Fair

The rapidly evolving landscape of PCBA manufacturing was prominently showcased during the 138th China Import and Export Fair in 2025, underscoring the sector's pivotal role within the global electronics market. According to a recent industry report by IPC, the global market for PCBAs is projected to reach $100 billion by 2025, driven by advancements in technology and increasing demand for smart electronics. This growth presents both challenges and opportunities for manufacturers, as they navigate complexities such as supply chain disruptions and the need for sustainable practices.

The fair highlighted innovative techniques and state-of-the-art automation tools, emphasizing the importance of efficiency and precision in production processes. With trends pointing towards increased miniaturization and higher integration of components, the focus on enhancing the quality and reliability of PCBA manufacturing processes is more crucial than ever for companies aiming to stay competitive in this dynamic market.

Emerging Technologies Transforming PCBA Manufacturing Processes in 2025

The 2025 China Import and Export Fair showcased significant advancements in PCBA (Printed Circuit Board Assembly) manufacturing processes, driven by emerging technologies that are reshaping the industry landscape. Key trends highlighted during the event indicate a shift towards automation and smart manufacturing, with the global PCBA market projected to reach $120 billion by 2026, growing at a CAGR of 5.7%. This transformation is largely attributed to the integration of artificial intelligence (AI) and machine learning (ML), which enhance quality control and increase production efficiency.

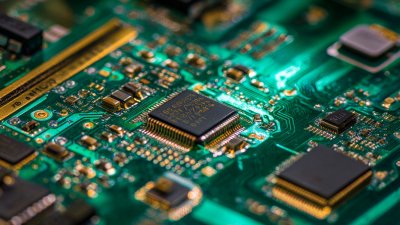

Additionally, innovations in materials and processes are gaining momentum. The adoption of advanced soldering techniques and environmentally friendly materials reflects a growing emphasis on sustainability in manufacturing. According to a report by ResearchAndMarkets, the use of lead-free solder is anticipated to capture over 75% of market share by 2025, underscoring the industry's shift towards eco-friendly practices. These emerging technologies not only optimize manufacturing processes but also facilitate the production of more complex and energy-efficient electronic components, catering to the evolving demands of the tech-savvy consumer.

Innovative Materials Driving Efficiency in PCBA Production at the 138th Canton Fair

The 138th Canton Fair showcased a significant shift in PCBA manufacturing, particularly with the introduction of innovative materials that enhance production efficiency. As the industry continues to evolve, the integration of advanced materials such as carbon nanotubes is starting to make waves. These materials not only improve the performance of electronic components but also contribute to more sustainable manufacturing practices, aligning with global trends toward eco-friendly production.

A recent product launch event highlighted breakthroughs in using carbon nanotube technology within X-ray sources, emphasizing the transformative potential of these materials in electronics. By leveraging their unique properties, manufacturers can achieve higher precision and better energy efficiency, thus revolutionizing traditional production processes. As more companies recognize the importance of innovation in material science, we can expect to see further advancements that will drive the future of PCBA manufacturing.

Sustainability Practices in PCBA Manufacturing: Trends and Impact in 2025

Sustainability practices in PCBA (Printed Circuit Board Assembly) manufacturing have become a focal point, particularly in light of the pressing environmental concerns and the need for responsible production methods. At the 2025 China Import and Export Fair, industry leaders showcased innovative practices that aim to reduce carbon footprints and enhance resource efficiency. Techniques such as using eco-friendly materials, optimizing manufacturing processes, and implementing waste reduction strategies were highlighted, demonstrating the industry's commitment to sustainability.

Sustainability practices in PCBA (Printed Circuit Board Assembly) manufacturing have become a focal point, particularly in light of the pressing environmental concerns and the need for responsible production methods. At the 2025 China Import and Export Fair, industry leaders showcased innovative practices that aim to reduce carbon footprints and enhance resource efficiency. Techniques such as using eco-friendly materials, optimizing manufacturing processes, and implementing waste reduction strategies were highlighted, demonstrating the industry's commitment to sustainability.

Moreover, the integration of advanced technologies such as AI and IoT in the manufacturing process has significantly impacted sustainability efforts. These technologies not only streamline production but also facilitate better tracking of environmental metrics, enabling companies to assess their impact in real-time. As consumers increasingly prioritize sustainable products, manufacturers are motivated to adopt greener practices, which in turn influences market trends and shapes the future of the PCBA sector. The convergence of technology and sustainability reflects a transformative shift toward a more responsible and eco-conscious manufacturing landscape.

Market Trends: Growth Projections for PCBA Manufacturing in Asia-Pacific by 2025

The market for Printed Circuit Board Assembly (PCBA) manufacturing in the Asia-Pacific region is poised for significant growth, with projections indicating a remarkable increase to $147.5 billion by 2035, at a compound annual growth rate (CAGR) of 4.7% starting in 2025. This expansion is largely driven by the escalating demand for consumer electronics, the ongoing evolution of automotive electronics, the deployment of 5G networks, and the rapid proliferation of Internet of Things (IoT) devices. These factors collectively demonstrate the integral role that PCBA manufacturing will play in meeting the technological demands of the future.

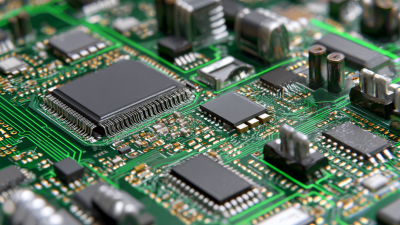

Moreover, the flexible PCB market is set to reach an impressive $61.75 billion by 2032, underscoring the growing trend towards miniaturization and flexibility in electronic designs. The introduction of advanced technologies is catalyzing this market, as manufacturers seek innovative solutions to meet the dynamic needs of various industries. Coupled with ongoing advancements in automation and inspection equipment for the electronics sector, the sector's trajectory suggests a robust and transformative era ahead for PCBA manufacturing in the Asia-Pacific market.

Industry 4.0: The Role of Automation and AI in the Future of PCBA Manufacturing

The advent of Industry 4.0 is revolutionizing PCBA (Printed Circuit Board Assembly) manufacturing, particularly through the integration of automation and artificial intelligence (AI). A report by MarketsandMarkets indicates that the global PCBA market is projected to reach $95.57 billion by 2026, driven by the increasing demand for electronics in various sectors. Automation is pivotal in streamlining manufacturing processes, reducing cycle times, and enhancing precision. Companies leveraging advanced robotics experience productivity increases of around 20% while significantly minimizing human error.

AI plays an equally crucial role by enabling predictive maintenance and real-time quality control. According to a study by McKinsey, the implementation of AI in manufacturing can lead to cost reductions of up to 25%. This transition facilitates a responsive manufacturing ecosystem where data-driven decisions enhance production efficiency. As the industry evolves, firms that adopt these technologies will not only optimize their operations but also position themselves competitively in an increasingly digital landscape. This fusion of automation and AI is not merely a trend; it is the future of PCBA manufacturing, preparing the industry for unprecedented growth and innovation.

Emerging Trends in PCBA Manufacturing Highlighted at 2025 China Import and Export Fair

| Trends | Description | Impact on PCBA | Implementation Year |

|---|---|---|---|

| Automation | Utilization of robotics for assembly and quality control. | Increased production speed and reduced labor costs. | 2024 |

| AI in Design | Leveraging artificial intelligence for circuit design optimization. | Enhanced efficiency and reduced design errors. | 2025 |

| Smart Manufacturing | Integration of IoT devices for real-time monitoring. | Improved traceability and informed decision-making. | 2025 |

| Sustainability | Focus on eco-friendly materials and processes. | Reduction in environmental impact and waste management. | 2025 |

| Flexible PCB | Usage of flexible printed circuit boards for advanced applications. | Enables lightweight and compact designs. | 2024 |

Related Posts

-

Understanding the Key Steps in Printed Circuit Board Assembly Process

-

Ultimate Guide to Choosing the Right PCBA Manufacturing Partner for Global Procurement

-

Challenges with Achieving Best PCB Printing Quality

-

Exploring Innovative Alternatives in PCB Design and Assembly for Global Buyers

-

How to Choose the Right Circuit Board Assembly Partner for Your Business Needs

-

How to Optimize Your PCB Fabrication Process for Enhanced Efficiency and Quality

MSIRobot