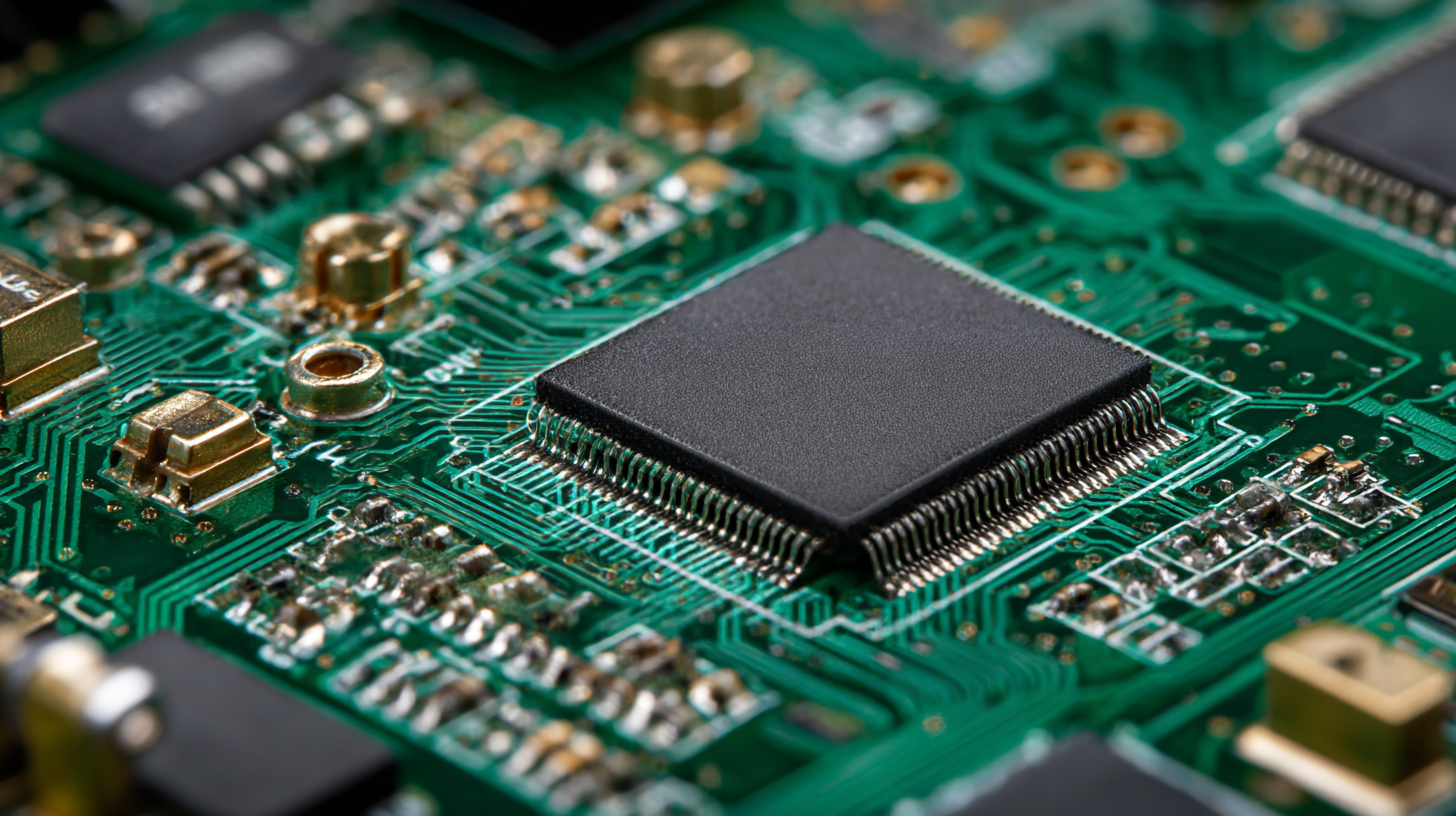

How to Choose the Best PCB Board for Your Electronic Projects

In the ever-evolving world of electronics, selecting the right PCB board is crucial for the success of your projects. According to a recent report by Research and Markets, the global PCB market is expected to reach $71.6 billion by 2026, driven by advances in technology and the increasing demand for electronic devices across various industries. With a plethora of options available, from single-sided to multi-layer boards, understanding the characteristics and applications of different PCB types is essential for engineers and hobbyists alike. This blog will explore the key factors to consider when choosing a PCB board, ensuring that your electronic projects not only meet design specifications but also achieve optimal performance and reliability. Whether you’re developing consumer electronics, automotive components, or industrial machinery, making an informed decision can vastly enhance your project's efficacy and longevity.

Key Considerations for Selecting the Right PCB Material for Your Project

When selecting the right PCB material for your electronic projects, it is crucial to consider several key factors that can significantly influence performance and reliability. The material type, thickness, and thermal conductivity are among the most critical considerations. For instance, FR-4 is a popular choice due to its excellent balance of mechanical strength and electrical insulation, making it suitable for a wide range of applications. According to market reports, the FR-4 market is projected to grow steadily, driven by an increase in consumer electronics and automotive applications, which highlights the ongoing demand for robust PCB materials.

Furthermore, with the burgeoning need for high-performance PCBs to support advanced technologies such as AI servers, manufacturers are increasingly investing in state-of-the-art facilities for PCB production. A recent investment announcement revealed that a leading PCB manufacturer will allocate $1 billion towards expanding its high-end PCB capabilities. This significant move underscores the industry's focus on enhancing material quality and production efficiency to meet rising demands.

The shift toward higher-grade materials, particularly those with improved thermal management properties, is essential as electronic devices become more complex and power-intensive. These considerations are paramount in ensuring the longevity and effectiveness of your electronic designs.

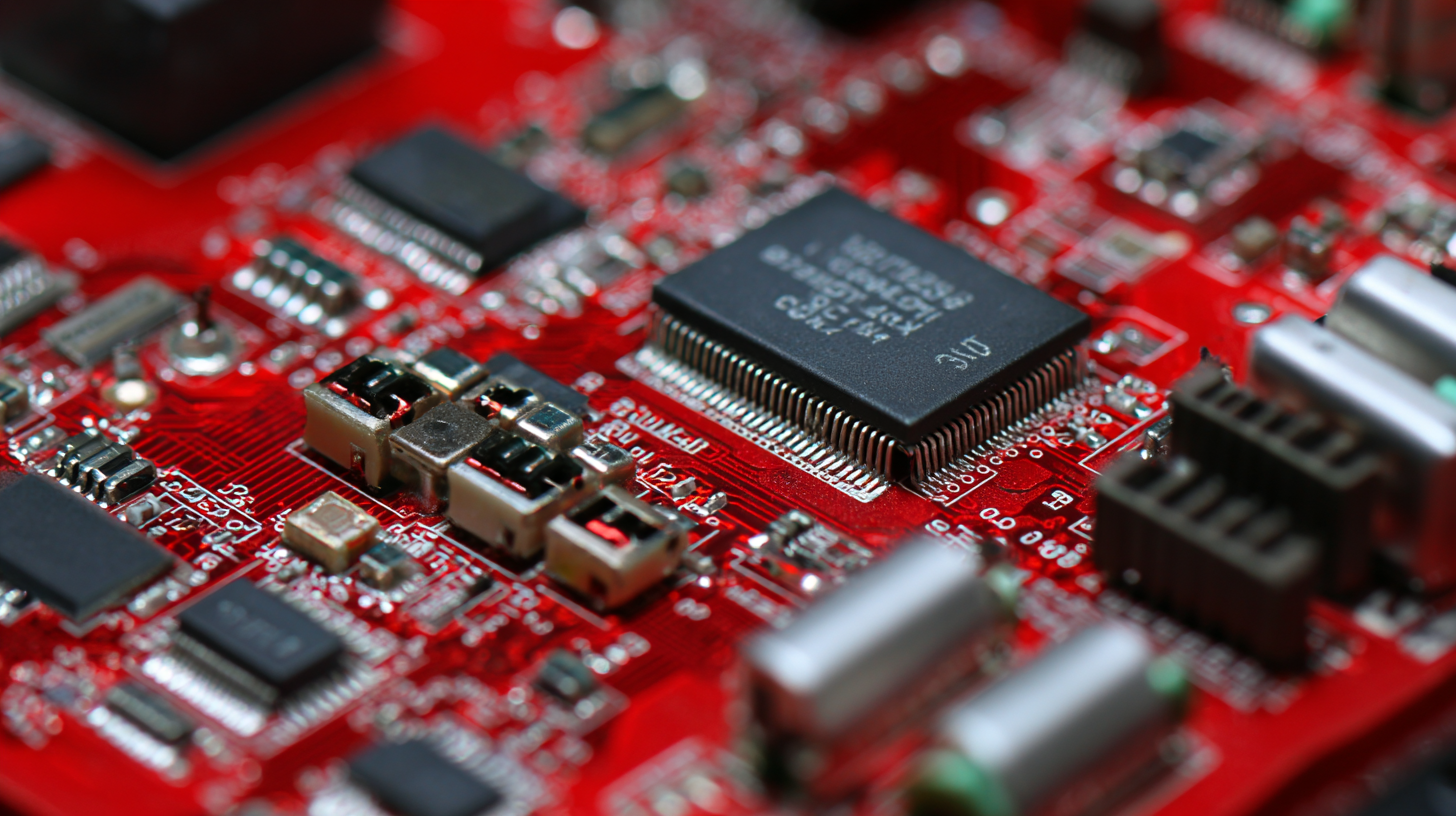

Understanding Different Types of PCB Designs: Rigid vs. Flexible vs. Rigid-Flex

When embarking on electronic projects, understanding the foundational types of PCB designs is crucial. Rigid PCBs are the most commonly used type, characterized by their solid substrate, which provides structural integrity. According to a report by MarketsandMarkets, the rigid PCB market is projected to reach $77.45 billion by 2025, driven by the growing demand for electronic devices in automotive and consumer electronics sectors. Their durability and cost-effectiveness make them suitable for projects that require consistent performance, such as smartphones and computers.

On the other hand, flexible PCBs offer unparalleled versatility, allowing for innovative designs in compact spaces. These boards can bend and twist, accommodating a variety of applications, especially in wearable technology and medical devices. Research indicates that the flexible PCB market is expected to grow at a CAGR of 10.5% from 2020 to 2025, as industries increasingly prioritize lighter and more complex circuit arrangements. Rigid-flex PCBs, which combine elements of both rigid and flexible designs, are also gaining traction. They provide enhanced durability and are often used in sophisticated applications like aerospace and military systems, where reliability is paramount.

Ultimately, the choice between rigid, flexible, or rigid-flex boards hinges on the specific demands of your project, including space constraints, thermal management, and environmental factors. Understanding these distinctions can significantly impact the success of your electronic designs and their performance in real-world applications.

Evaluating PCB Size and Complexity: Matching Your Board to Project Needs

When embarking on an electronic project, one of the critical considerations is selecting the right PCB board, particularly regarding size and complexity. According to a report by IPC (Institute of Printed Circuits), nearly 70% of engineering professionals agree that matching the PCB size to the project requirements is vital for enhancing performance and reliability. For minimalistic designs, a compact PCB can reduce signal interference and manufacturing costs, making it essential for projects with size limitations, such as wearable technology or IoT devices.

On the other hand, as projects scale in complexity — think multi-layer boards necessary for high-speed applications like telecommunications — the requirements shift significantly. The same IPC report indicates that multi-layer PCBs can provide approximately three times the circuit density compared to single-layer boards. This increased density allows for more features and functionalities without expanding the board size, thereby optimizing the design for intricate electronic applications. Understanding these dimensions is crucial for engineers who aim to achieve both functionality and efficiency in their designs.

Cost vs. Quality: Finding a Balance in PCB Manufacturing

Choosing the right PCB for your electronic projects involves a delicate balance between cost and quality. While it might be tempting to opt for the cheapest option available, it’s essential to consider the long-term impact of your decision. A low-cost PCB might save money upfront, but poor quality can lead to failures, increased downtime, and ultimately, higher overall costs.

Tip 1: Always evaluate the specifications required for your project. Consider factors such as layer count, thickness, and materials used. High-quality materials can significantly enhance the durability and performance of the PCB, which can save you from costly revisions later.

On the other hand, setting a budget is crucial. Tip 2: Add a buffer to your financial plan for unexpected expenses. Finding a manufacturer that offers a good compromise between price and quality can ensure you don’t overspend while still obtaining reliable boards. Communicating your needs clearly with the PCB manufacturer can lead to tailored solutions that fit both your budgetary constraints and quality requirements.

Tips for Assessing Manufacturer Specifications and Capabilities for Your PCB Needs

When selecting the best PCB board for your electronic projects, assessing manufacturer specifications and capabilities is crucial to ensure that the end product meets your needs. Start by evaluating the manufacturer's expertise in producing different types of PCBs, ranging from single-layer to complex multi-layer designs. Look for companies that highlight their experience with materials, technologies, and board thickness, as these factors will greatly influence performance and reliability.

Another important aspect to consider is the quality control processes in place. Verify if the manufacturer adheres to industry standards such as IPC-A-600 for workmanship and IPC-6012 for performance specifications. This can give you confidence that the PCBs produced will meet the necessary durability and operational requirements. Additionally, inquire about their testing methods and certifications, as these are indicators of the manufacturer's commitment to quality assurance.

Lastly, evaluate the manufacturer's production capabilities in terms of volume and lead time. If your project demands quick turnaround times or large quantities, ensure the manufacturer can accommodate these requirements without compromising quality. Check customer reviews and case studies to get insights into their reliability and capacity to handle projects similar to yours. This thorough approach will help you choose the best PCB board tailored to your specific electronic needs.

How to Choose the Best PCB Board for Your Electronic Projects - Tips for Assessing Manufacturer Specifications and Capabilities for Your PCB Needs

| Specification | Description | Importance |

|---|---|---|

| Material Type | Type of material used for PCB (e.g., FR-4, CEM-1) | High - Affects durability and thermal performance |

| Layer Count | Number of layers in the PCB | Medium - Determines complexity of the circuit |

| Trace Width | Width of copper traces on the PCB | High - Critical for current carrying capacity |

| Finish Type | Surface finish options (e.g., HASL, ENIG) | Medium - Affects solderability and shelf life |

| Tolerance | Precision of board fabrication and layout | High - Affects performance in tight spaces |

| Minimum Hole Size | Smallest drill hole dimension | Medium - Important for component fit |

| Production Time | Time taken from design to finished boards | Medium - Affects project timeline |

| Quantity | Number of PCBs required | High - Influences cost and production options |

MSIRobot