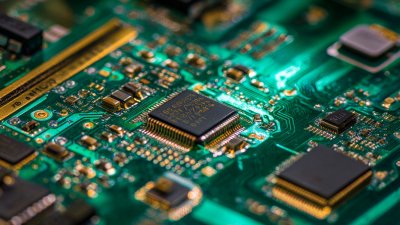

How to Choose the Right PCB Assembly Service for Your Electronic Projects

In today's fast-paced technological landscape, selecting the appropriate PCB assembly service is crucial for the success of your electronic projects. As the backbone of any electronic device, printed circuit boards (PCBs) require careful design and assembly to ensure optimal performance and reliability. With a myriad of service providers available, the challenges of distinguishing one company from another can be daunting. This guide aims to streamline your decision-making process, enabling you to choose a PCB assembly service that meets your specific needs.

When considering a PCB assembly service, several factors come into play, including the quality of materials used, the expertise of the staff, turnaround times, and pricing structures. It's essential to evaluate potential partners based not only on cost but also on their track record of reliability and the degree of customer service they provide. By understanding these elements, you can make a more informed choice that aligns with your project objectives and timelines. Ultimately, the right PCB assembly service can significantly impact the efficiency and success of your electronic designs, paving the way for innovation and growth in your projects.

Identifying Your Specific PCB Assembly Needs for Optimal Service Selection

When selecting a PCB assembly service for your electronic projects, it's crucial to first identify your specific needs. The complexity of your project, the volume of PCBs required, and the types of components you plan to use are all factors that will influence your choice. For instance, if you are working on a low-volume prototype, you may benefit from services that specialize in quick turnaround times and cost-effective solutions. In contrast, larger production runs might necessitate a service with advanced capabilities in mass production and quality assurance.

Tips: Look for a PCB assembly service that offers customization, as this can ensure you receive a product tailored to your specifications. Additionally, researching industry reports can provide insight into which services have shown consistent reliability and quality over time. For example, a recent analysis highlighted that companies utilizing AI in PCB fabrication experienced up to a 30% increase in manufacturing efficiency, which makes it essential to consider technological advancements when selecting your service provider.

Lastly, don’t overlook the importance of post-assembly support. Ensuring that your chosen service has a robust support system in place can greatly affect the smooth integration of your PCBs into your final product. Take the time to assess the support options available to maintain ongoing communication and assistance throughout your project timeline.

Evaluating the Experience and Expertise of PCB Assembly Providers

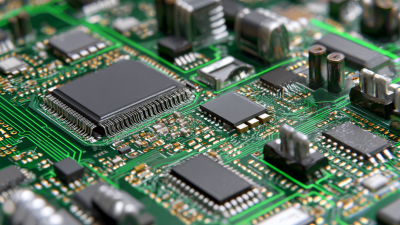

When selecting a PCB assembly service for your electronic projects, evaluating the experience and expertise of potential providers is crucial. An experienced PCB assembly partner will not only bring technical skills to the table but also a deep understanding of industry standards and compliance regulations. It is vital to assess how long the company has been in the industry, as well as its track record with projects similar to yours. Look for case studies or customer testimonials that highlight their capabilities in handling complex assemblies and problem-solving.

Moreover, consider the expertise of the engineering team within the assembly service provider. A qualified team should have diverse skills in various aspects of PCB design and manufacturing processes. Engaging with your chosen provider can offer insights into their approach toward design for manufacturability (DFM) and testability (DFT). Questions regarding their familiarity with different materials, assembly techniques, and quality control measures will further shed light on their proficiency. Prioritizing this evaluation will ensure that you partner with a provider who can meet your specific project needs effectively.

Comparing Cost Structures and Value Offered by Different Services

When selecting a PCB assembly service for your electronic projects, understanding the cost structures and value offered by different providers is crucial. Several factors contribute to the overall cost, including the complexity of the design, the quantity of boards, the type of components, and the assembly process required. Some services may offer lower initial costs but then charge significantly for faster turnaround times or specific quality assurances, while others might present a higher upfront cost but include comprehensive services that add value over time.

Evaluating the value offered by a PCB assembly service goes beyond just comparing prices. It's essential to consider aspects such as customer support, quality certifications, and turnaround times. A service that invests in advanced quality control processes may save you money in the long run by reducing the likelihood of defects and rework. Additionally, consider the level of communication and support you can expect throughout the project. Choosing a service that aligns with your project needs and budget while ensuring high-quality outputs will ultimately contribute to the success of your electronic projects.

Cost Comparison of PCB Assembly Services

Assessing Quality Assurance Measures in PCB Assembly Processes

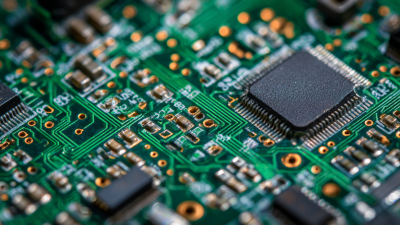

When selecting a PCB assembly service for your electronic projects, the quality assurance measures they employ are crucial in ensuring the reliability and performance of your final product. According to a report from IPC, the association connecting electronics industries, approximately 70% of PCB defects arise from inadequate quality control during assembly stages. This highlights the importance of partnering with a service that adheres to stringent quality assurance protocols.

One key aspect to assess is whether the assembly service follows IPC-A-610 standards, which provide guidelines for the acceptability of electronic assemblies. Services adhering to these standards are more likely to deliver PCBs that meet industry benchmarks, reducing the likelihood of failure in the field. Additionally, companies that incorporate automated optical inspection (AOI) in their processes, as noted in a study by TechInsights, can detect up to 98% of potential defects early in the production cycle. Investing in PCB assembly services that utilize advanced quality assurance technologies not only enhances product dependability but also fosters long-term customer satisfaction and brand loyalty.

How to Choose the Right PCB Assembly Service for Your Electronic Projects

| Criteria | Description | Importance Level |

|---|---|---|

| Quality Assurance | Assessing the procedures in place for ensuring the quality of assembled PCBs. | High |

| Certifications | Verification of ISO or IPC certifications to meet industry standards. | High |

| Turnaround Time | The time taken from order placement to delivery of the assembled PCB. | Medium |

| Cost | Overall pricing of the assembly service, including any additional fees. | High |

| Customer Support | Availability of support for inquiries before, during, and after the project. | Medium |

| Manufacturing Capabilities | Ability to handle various types of components and assembly methods. | High |

| Prototype Offering | Services that provide prototype production for testing purposes. | Medium |

Exploring Customer Support and Communication Channels in PCB Services

Choosing the right PCB assembly service for your electronic projects involves not only evaluating technical capabilities but also understanding the importance of effective customer support and communication channels. A responsive and knowledgeable support team can elevate your project, ensuring that questions and concerns are addressed promptly. This is crucial for maintaining timelines and achieving the desired quality.

**Tips:** Consider services that offer multiple communication methods, such as phone support, email, and live chat. This allows you to connect with them in your preferred manner. Also, assess their responsiveness during the initial inquiry; a quick reply indicates a commitment to customer service.

Furthermore, look for companies that provide clear and accessible documentation throughout the assembly process. This transparency helps you stay informed about the progress of your project and enables you to provide feedback effectively.

**Tips:** Evaluate the clarity and thoroughness of their project management tools; a well-structured platform can streamline communication and project tracking. Additionally, choose a provider that encourages regular status updates and offers dedicated points of contact for any issues that may arise.

Related Posts

-

Challenges with Achieving Best PCB Printing Quality

-

Understanding the Key Steps in Printed Circuit Board Assembly Process

-

How to Optimize Your PCB Fabrication Process for Enhanced Efficiency and Quality

-

2025 Top 10 PCB Electronics Innovations Transforming the Industry

-

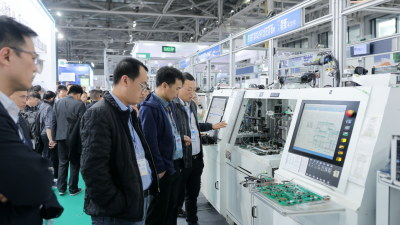

Emerging Trends in PCBA Manufacturing Highlighted at 2025 China Import and Export Fair

-

Navigating the 2025 PCB Design and Assembly Trends for Global Buyers

MSIRobot