Challenges with Achieving Best PCB Printing Quality

In recent years, China has established itself as a dominant force in the global manufacturing landscape, particularly in the field of electronics. Central to this industry is the process of pcb printing, which plays a pivotal role in determining the overall quality and performance of electronic devices.

However, achieving the best pcb printing quality presents a multitude of challenges for manufacturers, including variations in raw materials, technological advancements, and the ever-increasing demand for precision and reliability.

However, achieving the best pcb printing quality presents a multitude of challenges for manufacturers, including variations in raw materials, technological advancements, and the ever-increasing demand for precision and reliability.

As companies strive to maintain their competitive edge, they must navigate these complexities to enhance their pcb printing processes. This blog explores the inherent difficulties faced by manufacturers and the strategies they employ to overcome these obstacles, ultimately contributing to the remarkable rise of Chinese manufacturing prowess on the world stage.

Understanding the Importance of PCB Printing Quality in Global Manufacturing

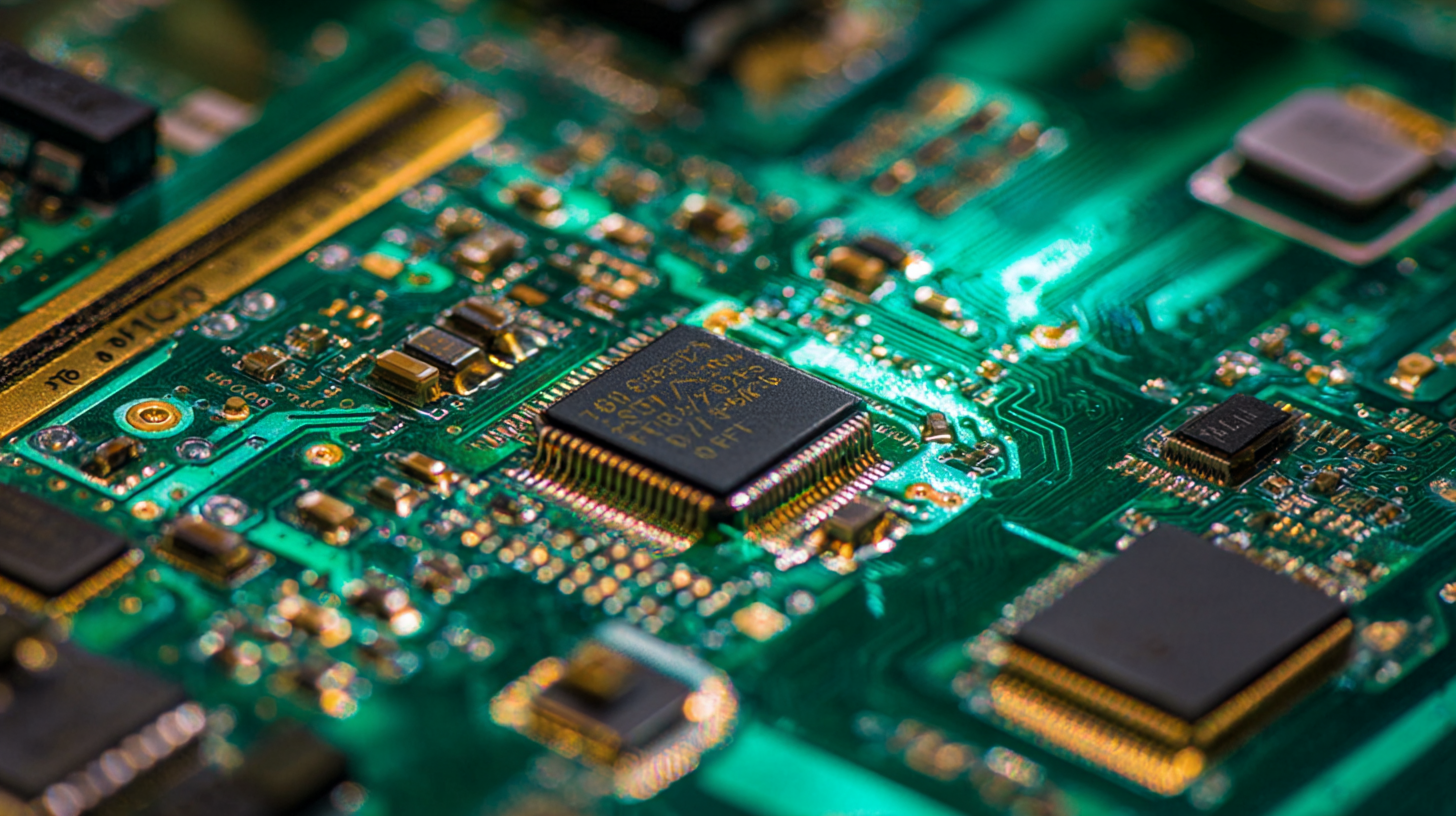

In the rapidly evolving landscape of global manufacturing, achieving high-quality PCB printing is paramount. Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, influencing the performance and reliability of devices across various industries. As manufacturers strive to produce intricate designs with tight tolerances, the quality of PCB printing directly impacts the transition from concept to execution. Discrepancies in printing can lead to defects, malfunctions, and ultimately, costly recalls, underlining the significance of rigorous quality control measures in the PCB manufacturing process.

Furthermore, understanding the importance of PCB printing quality extends beyond just the manufacturing floor. High-quality PCBs contribute to the overall efficiency of electronic systems, reducing power consumption and enhancing longevity. As technology continues to miniaturize and components become more densely packed, the stakes for PCB quality grow even higher. Manufacturers must invest in advanced printing technologies, employee training, and meticulous process monitoring to ensure consistent quality. In a global market where competitive advantage relies heavily on innovation and reliability, prioritizing PCB printing quality is not just beneficial; it is essential for sustainable success.

Challenges with Achieving Best PCB Printing Quality - Understanding the Importance of PCB Printing Quality in Global Manufacturing

| Challenge |

Impact on Quality |

Possible Solutions |

Importance Level (1-5) |

| Inconsistent Ink Viscosity |

Causes uneven printing |

Regular calibration and maintenance |

5 |

| Misalignment of Printing |

Leads to poor layer adhesion |

Use precision alignment tools |

4 |

| Substrate Variability |

Affects consistency and quality |

Standardize substrate materials |

5 |

| Environmental Factors (Humidity, Temp) |

Impacts drying and curing times |

Control production environment |

4 |

| Equipment Wear and Tear |

Can cause defects in prints |

Implement regular maintenance schedules |

5 |

Common Challenges Faced by Manufacturers in Achieving Optimal PCB Quality

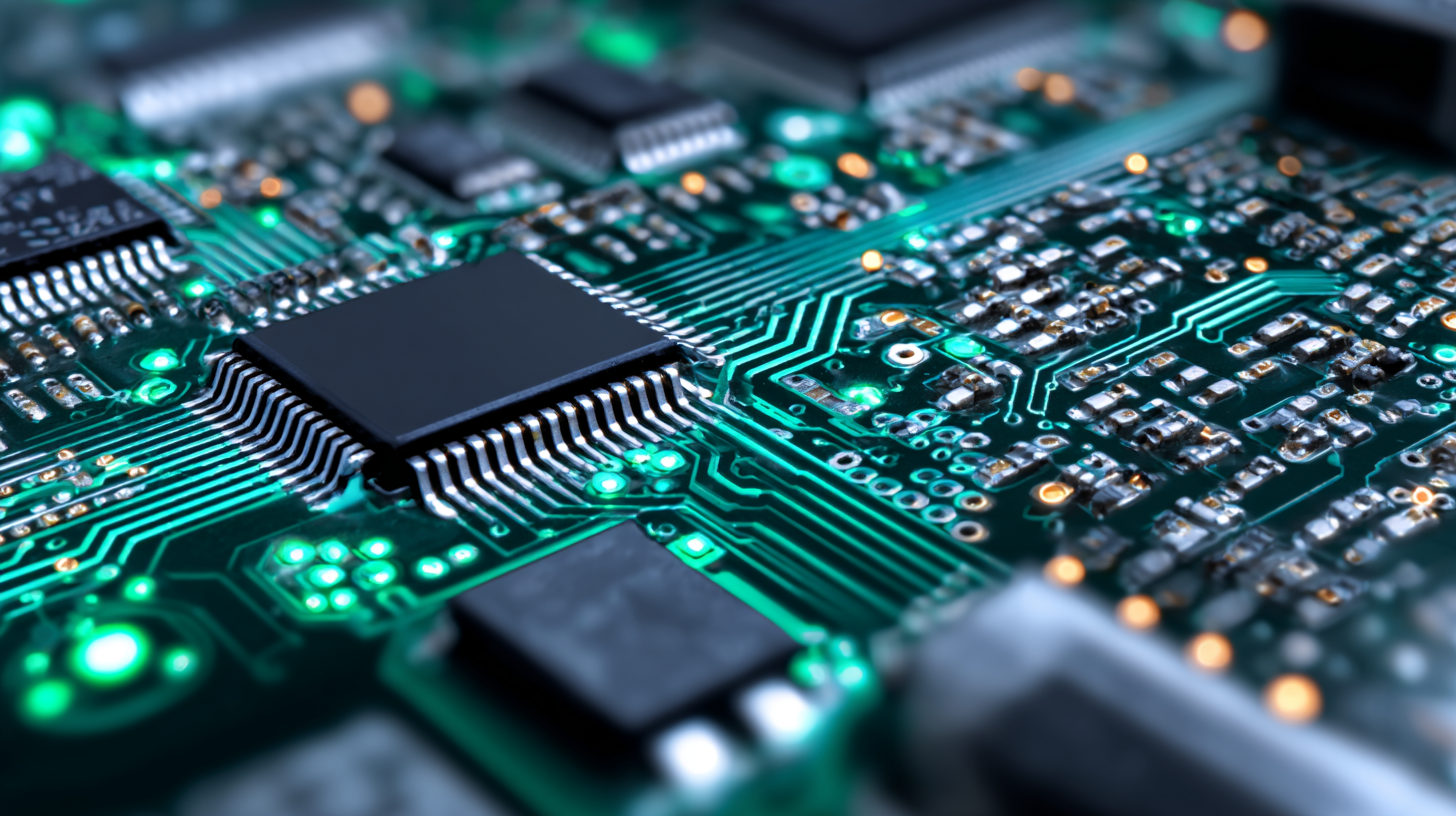

Achieving optimal quality in PCB printing is a complex process that manufacturers frequently navigate, facing numerous challenges along the way. One significant hurdle is maintaining precise alignment during the printing process. Misalignment can lead to defects such as copper shorts or open circuits, which, according to IPC's report on PCB defect rates, can account for up to 25% of production failures. Ensuring high-quality registration involves advanced technologies, including automated optical inspection systems, which can be costly to implement but are essential for reducing errors.

Another critical challenge is the control of printing parameters, such as ink viscosity and drying time. Variability in these factors can significantly influence the final output quality. A study from the International PCB Association indicates that 60% of process-related defects stem from improper ink management, underscoring the need for stringent controls and regular monitoring of printing conditions. Moreover, environmental factors like humidity and temperature can further complicate this, necessitating a comprehensive approach to process optimization that includes both equipment calibration and environmental regulation to meet the high standards expected in today's electronics manufacturing landscape.

Challenges with Achieving Best PCB Printing Quality

Innovative Solutions to Enhance PCB Printing Processes and Outcomes

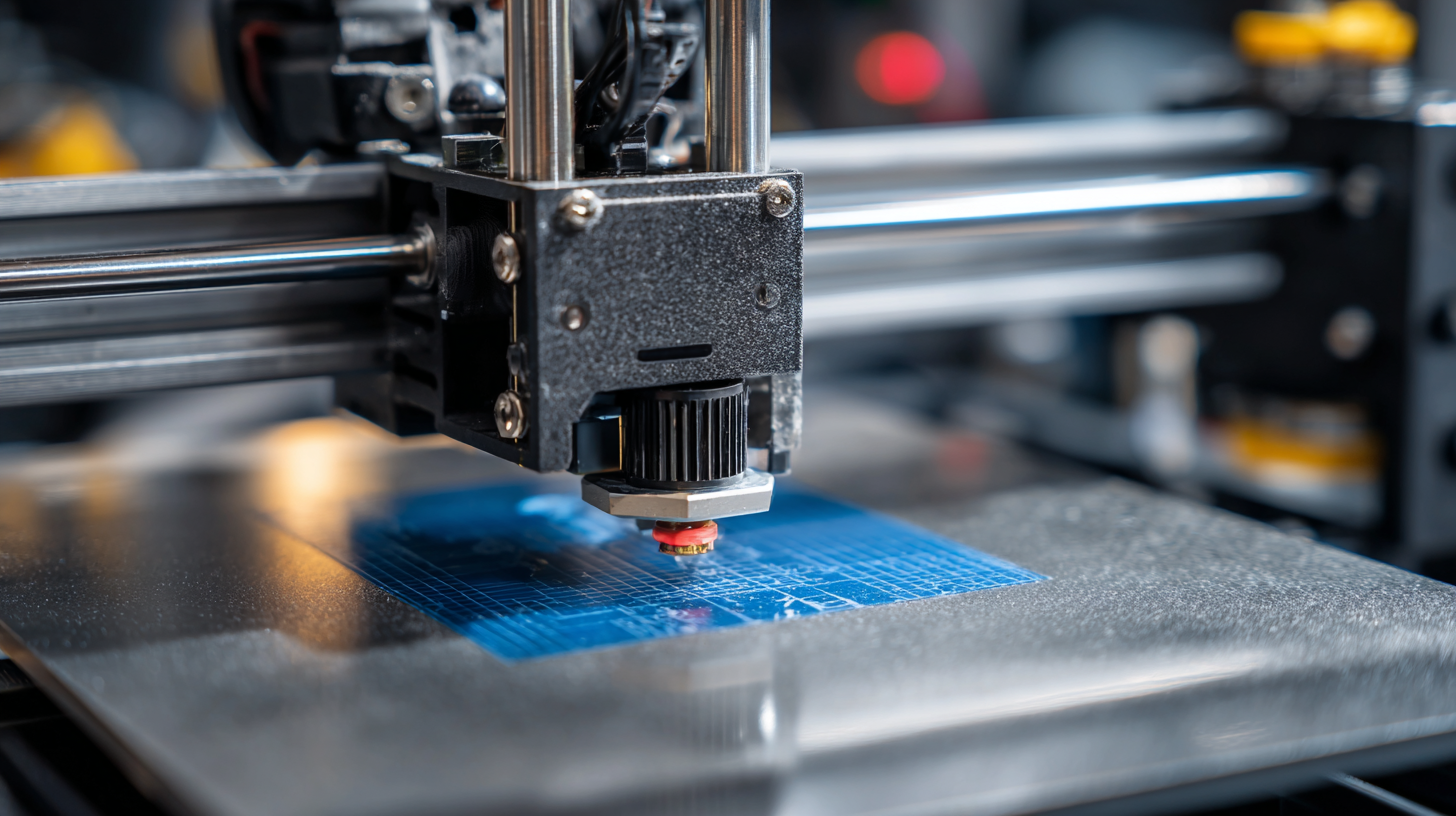

Achieving the highest quality in PCB printing is a multifaceted challenge that many manufacturers face today. One of the primary hurdles is maintaining precise alignment during the printing process, which can lead to misprints and subpar performance of the final product. Innovative solutions such as advanced registration systems and real-time monitoring of printing parameters have emerged to address these issues. By incorporating automated alignment technologies, companies can significantly reduce errors associated with manual setups, ensuring consistent quality across large volumes.

In addition to mechanical improvements, there is a growing emphasis on optimizing the ink formulation used in PCB printing. Innovative materials with better adhesion properties and conductivity can drastically enhance the printing process and the durability of the printed circuits. Companies are increasingly investing in research to develop eco-friendly inks that do not compromise on performance, thus meeting both quality standards and environmental regulations. By focusing on these innovative solutions, manufacturers can overcome traditional challenges in PCB printing and achieve superior outcomes that meet the demands of modern electronic applications.

The Role of Technology in Overcoming PCB Printing Challenges

Achieving the best PCB printing quality presents several challenges that manufacturers must navigate, but technology plays a pivotal role in overcoming these obstacles. One of the primary issues faced in PCB printing is the precision required in layer alignment and pad registration. High-resolution printing technologies, such as laser direct imaging (LDI) and advanced photolithography, significantly enhance accuracy, allowing for tighter tolerances and minimizing defects. By investing in these technologies, manufacturers can ensure that every layer aligns perfectly, which is crucial for high-performance circuit boards.

Another challenge lies in the material properties of substrates and inks used in PCB production. Variability in these materials can lead to inconsistencies in color, adhesion, and overall print quality. The advancement of materials science has led to the development of specialized inks that offer better adhesion, durability, and electrical performance. Additionally, the implementation of automated inspection systems equipped with AI and machine learning capabilities can swiftly identify issues in the printing process. These innovations not only enhance the overall quality but also reduce the time and costs associated with manual inspections and reworks, ultimately driving the industry toward higher standards of productivity and efficiency.

Future Trends in PCB Printing: Strategies for Maintaining Quality in Production

As the electronics industry evolves, maintaining high-quality standards in PCB printing remains a significant challenge. In the face of increasing miniaturization and complexity of circuits, manufacturers must adopt innovative strategies to ensure consistent quality. According to a recent IPC report, nearly 20% of PCBs produced experience defects due to issues in the printing process, highlighting the urgent need for improved quality control measures.

Future trends in PCB printing point towards the integration of advanced technologies such as AI-driven analytics and automated inspection systems. By leveraging real-time data, manufacturers can identify and address potential defects early in the production cycle. A study from Research and Markets estimates that the global PCB market will reach $90 billion by 2026, underscoring the necessity for strict quality maintenance strategies to meet growing demand. Moreover, implementing high-resolution printing techniques and investing in precision machinery are expected to enhance output quality while reducing waste, further fortifying the position of companies that prioritize quality in their production processes.