2025 Top Trends in Circuit Board Manufacturing You Need to Know

As we approach 2025, the landscape of circuit board manufacturing is evolving at a remarkable pace, propelled by advancements in technology and shifting market demands. Understanding the key trends that are set to dominate this industry is essential for manufacturers, engineers, and stakeholders who aim to stay competitive in a rapidly changing environment. This article explores the top trends in circuit board manufacturing that you need to be aware of, focusing on innovations, sustainable practices, and the increasing integration of automation and smart technologies.

The circuit board manufacturing sector is witnessing transformative changes influenced by the rise of electric vehicles, the Internet of Things (IoT), and high-demand electronics. As these technologies continue to shape consumer behavior and industries, manufacturers must adapt and innovate to meet new challenges. Furthermore, sustainability has become a critical concern, leading to eco-friendly materials and processes gaining prominence. This evolving landscape not only presents opportunities but also necessitates a strategic approach to leverage the latest developments effectively, ensuring the future of circuit board manufacturing remains bright and robust.

Emerging Technologies Transforming Circuit Board Manufacturing in 2025

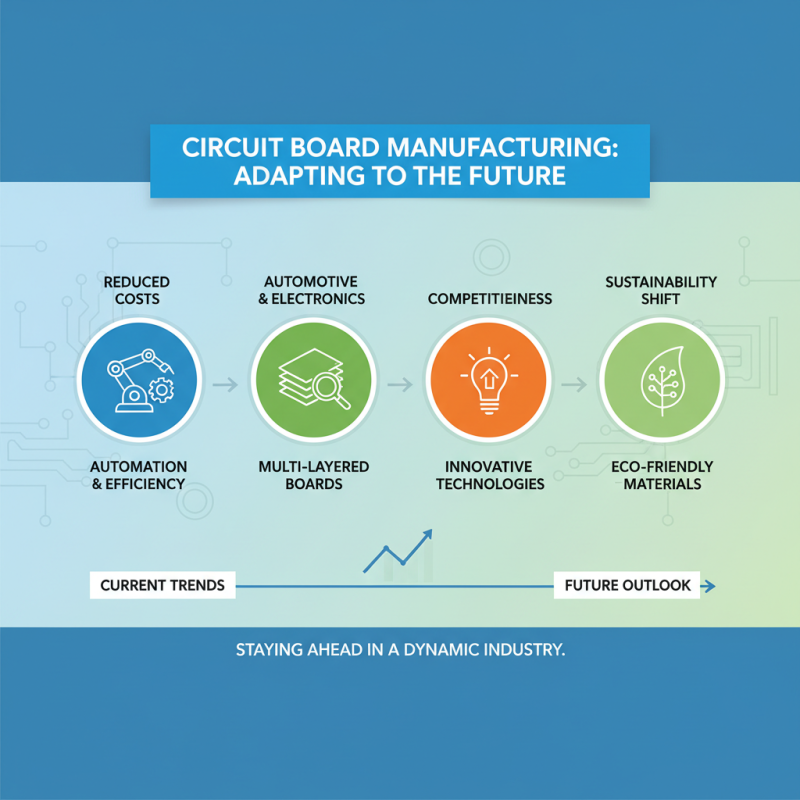

In 2025, the landscape of circuit board manufacturing is set to experience significant transformations driven by emerging technologies. Leading the charge is the rise of automation, which is anticipated to improve production efficiency by up to 30%, according to a recent report by the International Electronics Manufacturing Initiative (IEMI). Automated systems not only streamline operations but also minimize human error, significantly enhancing the consistency and quality of the circuit boards produced.

Furthermore, the integration of artificial intelligence (AI) into the manufacturing process is expected to revolutionize design and testing phases. AI algorithms can analyze complex data sets faster than human engineers, allowing for optimization of circuit layouts and rapid identification of potential defects. A study by the Institute of Electrical and Electronics Engineers (IEEE) forecasts that AI adoption in electronics manufacturing could lead to a reduction in design time by as much as 25%. These advancements indicate a shift towards more intelligent manufacturing processes, which are crucial as the demand for increasingly complex and miniaturized electronic components continues to rise, influenced by sectors such as 5G technology and the Internet of Things (IoT).

In addition to automation and AI, the sustainability movement is prompting circuit board manufacturers to embrace eco-friendly practices and materials. By 2025, it is estimated that at least 50% of new circuit boards will be produced using recyclable or biodegradable materials, as manufacturers respond to growing environmental regulations and consumer demand for greener products. This shift not only aligns with corporate social responsibility goals but also addresses the critical issue of electronic waste, a growing concern in the industry today.

2025 Top Trends in Circuit Board Manufacturing You Need to Know

| Trend | Description | Impact on Manufacturing | Year of Adoption |

|---|---|---|---|

| Advanced Materials | Use of new substrates like flexible and eco-friendly materials. | Improves design flexibility and reduces environmental impact. | 2025 |

| AI and Machine Learning | Integration of AI to optimize manufacturing processes. | Enhances efficiency and reduces defect rates. | 2024 |

| IoT in Manufacturing | Utilizing IoT for real-time monitoring and control. | Increases operational visibility and proactive maintenance. | 2025 |

| 3D Printing | Adoption of 3D printing for rapid prototyping. | Shortens product development cycles and reduces costs. | 2025 |

| Automation and Robotics | Increased use of automation for assembly and inspection. | Reduces labor costs and improves precision. | 2024 |

Sustainability Practices in Circuit Board Production: Trends and Innovations

Sustainability is becoming increasingly crucial in circuit board manufacturing as the industry recognizes its role in environmental preservation. One of the key trends is the adoption of eco-friendly materials. Manufacturers are exploring alternatives to traditional substrates and laminates that are often derived from petrochemicals. Materials like recycled plastics and bio-based substrates are gaining traction, offering a lower environmental footprint while maintaining performance standards. This not only helps in reducing waste but also addresses regulatory pressures for greener production processes.

Another significant development is the implementation of closed-loop manufacturing systems. These systems focus on reusing and recycling waste materials generated during production. By integrating processes that allow for the recovery of metals and other valuable components, manufacturers can significantly decrease their waste output. Innovations such as automated sorting technologies and advanced separation techniques are being employed to enhance the efficiency of these processes, ultimately lowering costs and minimizing environmental impact. This trend towards a circular economy is not only appealing from an ecological standpoint but also provides economic advantages by optimizing resource usage and reducing reliance on virgin materials.

Sustainability Practices in Circuit Board Production: Trends and Innovations

The Impact of AI and Automation on Circuit Board Manufacturing Efficiency

The integration of AI and automation in circuit board manufacturing is transforming the industry, driving significant improvements in efficiency and productivity. With advanced machine learning algorithms, manufacturers can optimize production processes by predicting equipment failures before they occur, reducing downtime and minimizing costs. Automated quality control systems equipped with AI can analyze defects in real-time, ensuring high levels of precision and allowing for immediate corrective actions, thus significantly enhancing the overall manufacturing yield.

Furthermore, automation is streamlining repetitive tasks that once required human intervention, such as soldering and assembly. Robots can operate around the clock with minimal supervision, resulting in faster production cycles and consistent output. This shift not only boosts operational efficiency but also allows human workers to focus on more complex and strategic aspects of circuit board design and development. The collaborative synergy between human expertise and automated processes is setting new benchmarks for efficiency in manufacturing, making it an essential trend to watch in the coming years.

Future Materials: Advancements in PCB Substrates and Components

As the electronics industry evolves, the focus on advancing printed circuit board (PCB) substrates and components is becoming increasingly crucial. In 2025, we can expect significant innovations in materials that enhance performance, reliability, and sustainability in circuit board manufacturing. Emerging materials such as flexible substrates and high-frequency laminates will pave the way for more compact designs and better electrical performance, catering to the booming demand for compact devices in today's tech-driven world.

Tips: When exploring new materials for PCBs, always consider the specific application requirements. Flexible substrates can be ideal for wearable technology, while high-frequency laminates are a must for telecommunications and aerospace applications. Always conduct thorough testing to ensure your chosen materials meet the necessary standards.

Another exciting trend is the integration of environmentally friendly materials into PCB production. Biodegradable substrates not only reduce the environmental impact but also meet the growing consumer demand for sustainable electronics. By utilizing these innovative materials, manufacturers can achieve compliance with stricter regulations, ultimately benefiting both the planet and their business prospects.

Tips: Collaborating with suppliers who specialize in sustainable materials can open up new avenues for product development. Additionally, actively seeking feedback from end-users can guide material choices that enhance overall functionality and user experience.

Market Dynamics: Key Players and Predictions for Circuit Board Manufacturing

The circuit board manufacturing industry is witnessing dynamic shifts, driven by technological advancements and changing market needs. Key players in the sector are focusing on automation, which enhances efficiency and reduces production costs. As demand for high-quality, multi-layered boards grows in sectors like automotive and consumer electronics, companies must adapt their strategies and invest in innovative technologies to stay competitive. Industry predictions indicate a continued rise in the adoption of environmentally-friendly materials and processes, reflecting a broader shift towards sustainability.

Tips: When evaluating potential suppliers or partners in circuit board manufacturing, consider their commitment to sustainable practices and innovation. Look for companies that demonstrate a clear understanding of industry trends and show a willingness to adapt to changing customer requirements.

Furthermore, the collaboration between manufacturers and research institutions is becoming increasingly important. This partnership fosters the development of cutting-edge technologies and helps address common challenges in the industry, such as supply chain disruptions. Companies that leverage these collaborations will be better equipped to navigate future uncertainties and drive growth effectively.

Tips: Networking within industry forums can provide valuable insights into emerging trends and technologies. Engaging with experts can help identify strategic opportunities for collaboration and innovation in circuit board manufacturing.

Related Posts

-

Exploring Sustainable Circuit Board Manufacturing Alternatives for Eco-Friendly Solutions

-

Navigating Import Export Certifications for the Best Circuit Board Procurement Strategies

-

Best PCB Electronics: A Comprehensive Comparison of Top Choices for Your Projects

-

Printed Circuits vs Traditional Circuits Which Technology Reigns Supreme

-

Ultimate Guide to Choosing the Right PCBA Manufacturing Partner for Global Procurement

-

Navigating the 2025 PCB Design and Assembly Trends for Global Buyers

MSIRobot