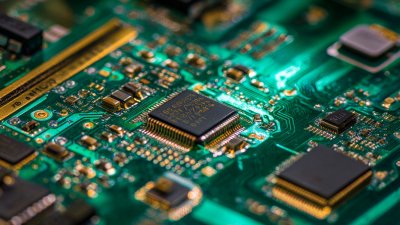

2025 Top 10 PCB Electronics Innovations Transforming the Industry

As the electronics industry evolves at an unprecedented pace, the significance of printed circuit boards (PCBs) becomes increasingly pronounced. The innovations surrounding PCB electronics are not merely enhancing existing technologies but are catalyzing a transformative shift within the sector.

In our exploration of the "2025 Top 10 PCB Electronics Innovations Transforming the Industry," we will delve into groundbreaking developments that are set to redefine efficiency, sustainability, and functionality in electronics manufacturing.

From advanced materials that promise better performance to cutting-edge design methodologies that streamline production, these innovations represent a confluence of creativity and technology. Each development is a testament to the ongoing quest for enhanced capabilities within PCB electronics, aimed at meeting the rising demands of modern applications. As we navigate through the anticipated breakthroughs, it becomes evident that the future of PCB technology holds immense potential, influencing everything from consumer gadgets to critical infrastructure.

Join us as we uncover the top innovations poised to shape the landscape of PCB electronics by 2025.

Revolutionizing Design: Advanced PCB Layout Techniques and Software Innovations

The rapid evolution of PCB design is fundamentally reshaping the electronics landscape, driven by advanced layout techniques and innovative software solutions. According to the latest industry reports, the global PCB market is forecasted to reach $85 billion by 2025, highlighting the pressing need for efficiency and precision in design practices. Advanced software tools now integrate artificial intelligence and machine learning algorithms, significantly optimizing the design process by automatically detecting and correcting potential issues. This not only enhances performance but also reduces the time required for product development.

Moreover, cutting-edge techniques such as HDI (High-Density Interconnect) and embedded components are becoming increasingly prevalent. These innovations allow designers to create more compact and high-performance circuits, catering to the growing demand for miniaturization in devices ranging from smartphones to medical equipment. According to a survey by IPC, 72% of manufacturers reported that adopting these advanced techniques has drastically improved their production capacity and reliability. With the implementation of such design innovations, the future of PCB electronics looks poised for groundbreaking advancements, ultimately benefiting both manufacturers and consumers alike.

Smart Materials: The Rise of Flexible and Printable Circuit Boards

The advent of smart materials is revolutionizing the PCB electronics industry, particularly through the development of flexible and printable circuit boards. These innovative materials allow for circuits to be designed and produced in unconventional shapes and sizes, offering unparalleled versatility. Unlike traditional rigid PCBs, flexible circuit boards can bend, twist, and conform to various surfaces, making them ideal for applications in wearable technology, medical devices, and compact electronic gadgets. This adaptability not only enhances the design possibilities but also helps reduce the overall weight and size of electronic products.

Moreover, printable circuit boards enable a more streamlined and cost-effective manufacturing process. Advances in ink formulations and printing techniques allow for the direct application of conductive materials onto substrates, significantly reducing production time and material waste. This shift towards additive manufacturing aligns with environmental sustainability efforts, as it minimizes the reliance on traditional, resource-intensive PCB fabrication methods. As smart materials continue to evolve, the impact on the electronics landscape will be profound, paving the way for innovative products with enhanced functionality and performance.

AI and Machine Learning: Enhancing PCB Manufacturing Efficiency and Quality

The integration of AI and machine learning in PCB manufacturing is revolutionizing the industry by enhancing efficiency and quality. These advanced technologies enable manufacturers to optimize production processes through predictive analytics, reducing defects and minimizing waste. By analyzing vast amounts of data in real time, AI algorithms can identify patterns that human operators might overlook, leading to better decision-making and improved product reliability.

**Tips:** To fully leverage AI in your PCB production, consider investing in training for your team on data analysis and machine learning tools. Encouraging a culture of continuous learning will ensure your workforce is equipped to adapt to these innovations quickly and effectively.

Moreover, AI-driven automation helps streamline workflows, allowing for faster turnaround times without sacrificing quality. With machine learning models, manufacturers can continuously improve their processes by learning from past experiences and adjusting to emerging challenges dynamically. This proactive approach not only enhances productivity but also fosters innovation, enabling companies to stay competitive in a fast-evolving market.

**Tips:** Regularly review and update your machine learning models as new data becomes available. This practice will keep your systems aligned with current trends and performance metrics, ensuring optimal operational outcomes.

Sustainability in PCB Production: Eco-Friendly Materials and Processes

The landscape of printed circuit board (PCB) production is undergoing a significant transformation, with sustainability at the forefront of innovation. As the electronics industry grapples with environmental concerns, manufacturers are increasingly adopting eco-friendly materials in their PCB production processes. Biodegradable substrates and halogen-free laminates are becoming commonplace, offering alternatives that reduce the ecological footprint while maintaining performance standards. By integrating sustainable materials, companies can not only comply with environmental regulations but also appeal to a growing market of eco-conscious consumers.

In addition to materials, the production processes themselves are evolving. Innovative techniques such as water-based soldering and the reduction of chemical waste are gaining traction within the industry. These advancements not only minimize harmful emissions but also enhance the overall efficiency of PCB manufacturing. As companies strive to decrease their environmental impact, investments in cleaner technologies and practices will be crucial. The shift towards sustainability in PCB production not only benefits the planet but also positions manufacturers as leaders in a market that increasingly values eco-friendly solutions.

2025 Top 10 PCB Electronics Innovations

The Internet of Things: Driving Demand for Highly Integrated PCB Solutions

The Internet of Things (IoT) is fundamentally reshaping the landscape of electronic devices, driving the demand for highly integrated PCB (Printed Circuit Board) solutions. According to a recent report by Research and Markets, the global IoT market is anticipated to grow from $250 billion in 2020 to over $1 trillion by 2025, highlighting a significant surge in connected devices that rely heavily on advanced PCB technologies. This integration allows for enhanced functionality, reduced power consumption, and smaller form factors, meeting the stringent requirements of smart devices prevalent in sectors such as healthcare, automotive, and consumer electronics.

Moreover, as IoT applications become more sophisticated, the need for multi-layered, high-density interconnect (HDI) PCBs rises. The IPC's "Global Market for PCBs" report indicates that HDI PCBs are expected to witness a compound annual growth rate (CAGR) of 10% through 2025, fueled by innovations in fabrication techniques and materials. Companies are now investing in new manufacturing processes, including embedded components and nano-coating technologies, to produce PCBs that not only fit into smaller spaces but also withstand the environmental challenges associated with IoT applications. This technological evolution will be crucial for supporting the increasing complexity and connectivity of future electronic systems.

Related Posts

-

Challenges with Achieving Best PCB Printing Quality

-

Navigating the 2025 PCB Design and Assembly Trends for Global Buyers

-

How to Optimize Your PCB Fabrication Process for Enhanced Efficiency and Quality

-

Best PCB Electronics: A Comprehensive Comparison of Top Choices for Your Projects

-

Exploring Innovative Alternatives in PCB Design and Assembly for Global Buyers

-

Navigating Import Export Certifications for the Best Circuit Board Procurement Strategies

MSIRobot