Navigating the 2025 PCB Design and Assembly Trends for Global Buyers

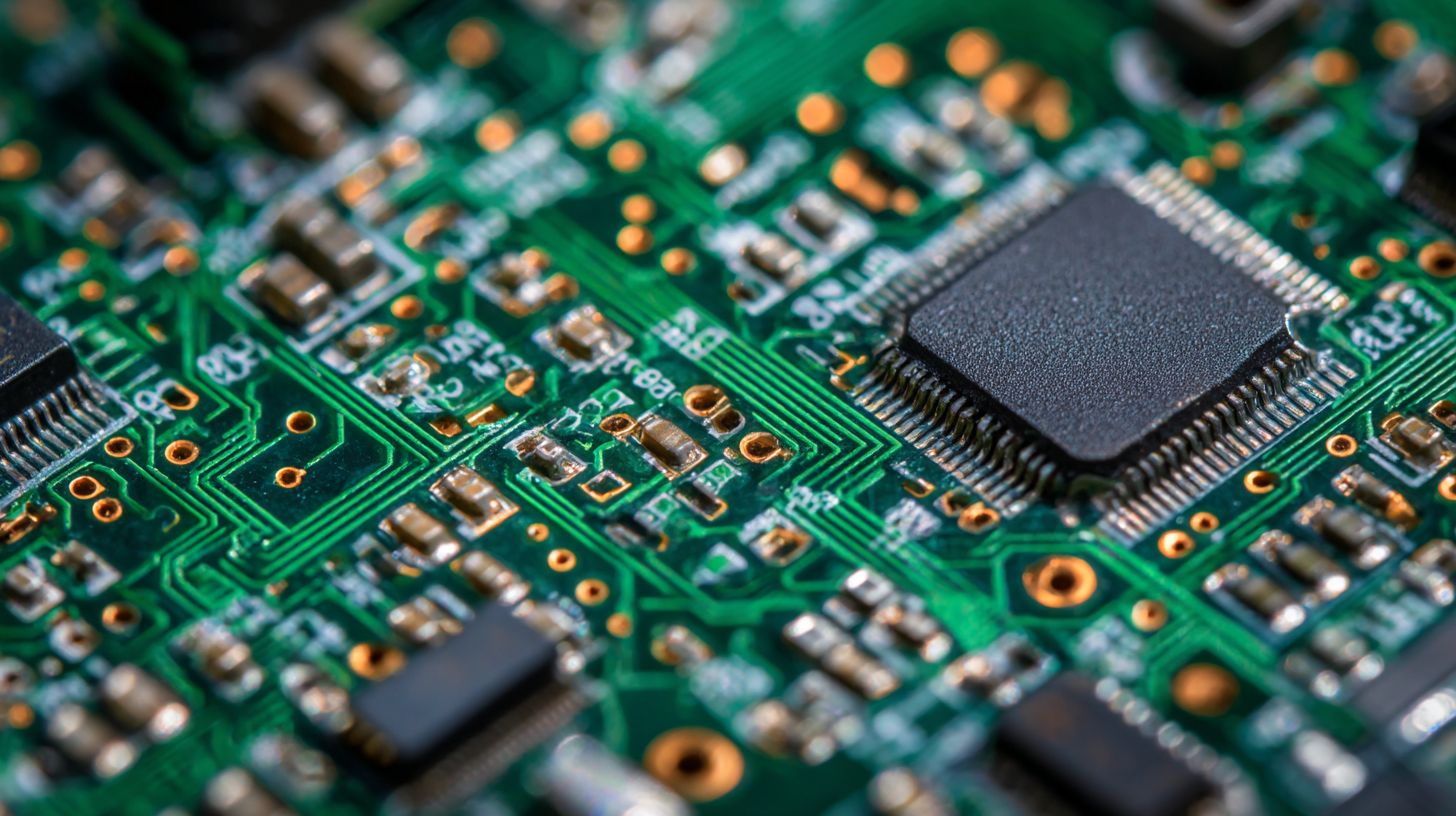

As the world gears up for the technological innovations of 2025, the landscape of PCB design and assembly is witnessing significant transformations, underscored by China's remarkable export strength in the electronics manufacturing sector. According to a recent report by Research and Markets, the global PCB market is projected to reach $94.6 billion by 2025, driven by the increasing demand for advanced electronics in automotive, consumer electronics, and telecommunications. With Chinese manufacturers leading the charge, exemplified by companies achieving over 30% of the global PCB production share, the implications for buyers are profound. Navigating these trends is essential for global buyers looking to capitalize on emerging opportunities, improve supply chain efficiency, and ensure the integration of cutting-edge design practices in their projects, making a deep understanding of the evolving PCB design and assembly landscape vital as we move toward this pivotal year.

Identifying Key Attributes of Quality PCB Suppliers in 2025

In 2025, the PCB (Printed Circuit Board) industry is expected to see significant shifts driven by advancements in technology and changing market demands.

Global buyers seeking quality PCB suppliers must pay closer attention to several key attributes that denote reliability and excellence in manufacturing. According to a recent report by the IPC, the demand for PCBs is projected to grow at a CAGR of 5.1% over the next five years, underscoring the importance of choosing suppliers that are adaptable and forward-thinking.

One critical attribute is a supplier’s commitment to environmental sustainability.

Growing regulatory pressures and consumer awareness are prompting manufacturers to adopt eco-friendly practices.

A survey by TechValidate found that 74% of electronics companies now prioritize suppliers with robust sustainability certifications.

Additionally, advanced technological capabilities are becoming increasingly crucial. Suppliers equipped with automated assembly lines and AI-driven quality control processes demonstrate a commitment to enhancing productivity and minimizing errors, which is essential in the highly competitive landscape of PCB production.

Furthermore, strong customer support and transparent communication are vital for global buyers. Reliable suppliers provide detailed product information, swift response times, and effective problem-solving strategies, which can significantly reduce lead times and improve overall project outcomes.

As the landscape evolves, understanding these key attributes will empower buyers in selecting the most suitable PCB partners for their needs.

Evaluating Supplier Capabilities: Technical Expertise and Innovation

In the rapidly evolving PCB design and assembly landscape, evaluating supplier capabilities is paramount for global buyers. According to a recent industry report by IPC, the global PCB market is projected to reach $85 billion by 2025, highlighting the growing demand for innovation and technical expertise in this sector. As technology advances, it is essential for suppliers to demonstrate not only their technical skills but also their ability to adapt and innovate in response to market trends.

**Tip:** When assessing potential suppliers, look for those who prioritize continuous improvement and invest in R&D. This commitment often translates into cutting-edge solutions that can significantly enhance product quality and reduce time-to-market.

Furthermore, advancements in materials and manufacturing processes are reshaping the design landscape. The use of flexible PCBs, for instance, is expected to grow by 10% annually, driven by their versatility in applications ranging from consumer electronics to automotive sectors. Buyers should seek suppliers that showcase a strong knowledge base in emerging technologies, as these capabilities are crucial for staying competitive.

**Tip:** Engage with suppliers to understand their recent projects and innovations. A portfolio that reflects a diverse range of successful collaborations is a good indicator of a supplier’s ability to handle complex projects effectively.

Navigating the 2025 PCB Design and Assembly Trends

Sustainable Practices: What to Look For in PCB Manufacturing Partners

As the demand for printed circuit boards (PCBs) continues to rise, global buyers must place greater emphasis on

sustainable practices

when selecting manufacturing partners. Sustainable PCB manufacturing not only emphasizes eco-friendly materials and processes but also ensures compliance with stringent environmental regulations. By choosing partners who prioritize sustainability, businesses can not only minimize their carbon footprint but also enhance their brand reputation.

Tips for Identifying Sustainable PCB Manufacturers:

Firstly, look for partners that use green materials such as lead-free solder and recyclable substrates. Understand their supply chain practices; manufacturers who source their components responsibly and reduce waste during production demonstrate a commitment to sustainability.

Additionally, inquire about their energy use. A PCB manufacturer that implements

renewable energy sources

in its operations is likely to be more environmentally responsible. Certifications, such as ISO 14001, can also serve as indicators that a company follows robust environmental management systems, ensuring continuous improvements in their sustainability efforts.

By focusing on these sustainable practices, global buyers can forge partnerships that align with their

corporate responsibility goals

while fostering a healthier planet.

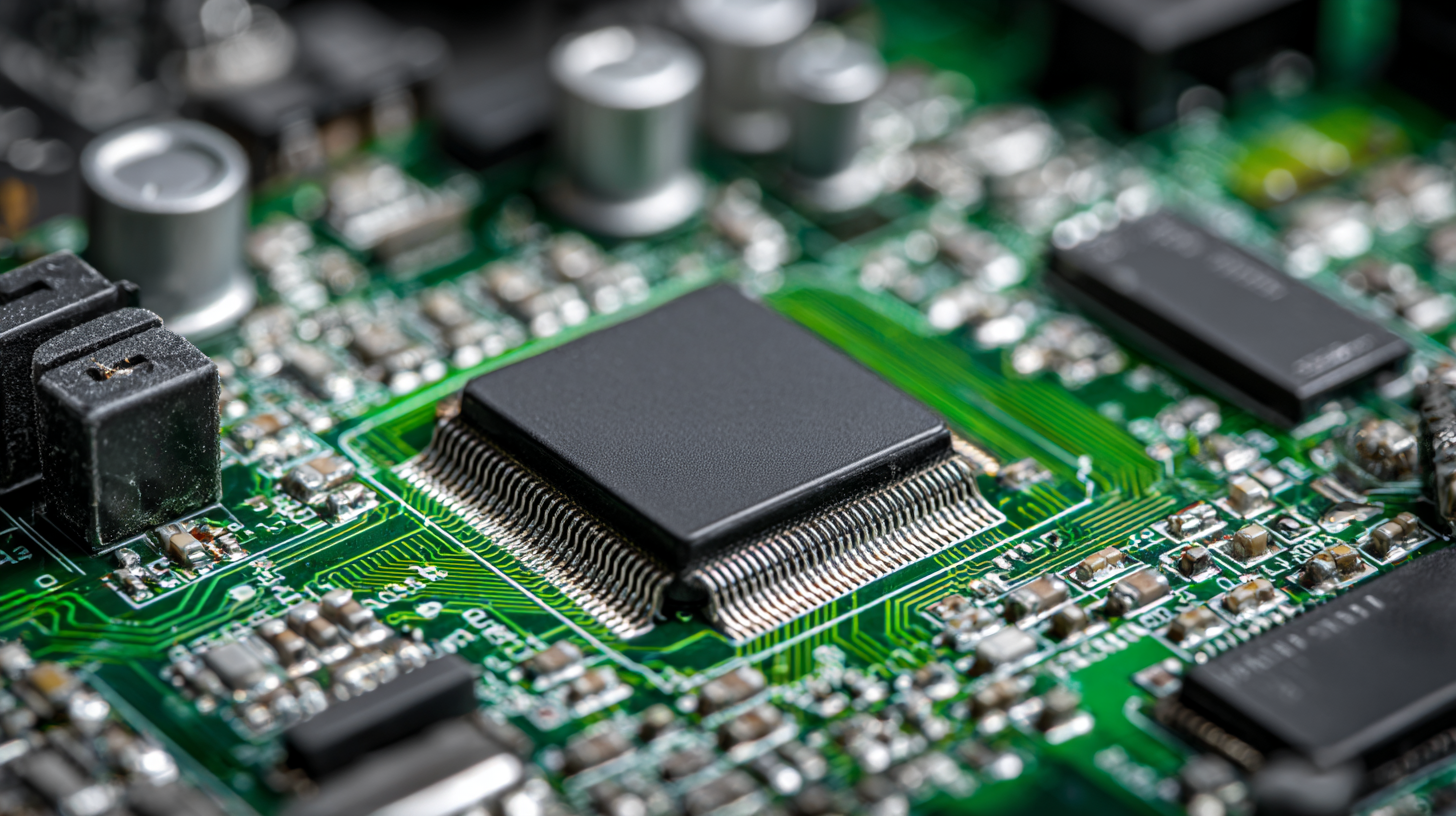

Understanding Global Trends: Supply Chain Dynamics Impacting PCB Buying

As we approach 2025, the dynamics of the printed circuit board (PCB) market are evolving rapidly, particularly under the influence of global supply chain considerations. The recent emphasis on the critical role of PCB manufacturing in national development highlights how integral these components are for a wide array of electronic devices across various industries. Buyers must navigate these supply chain dynamics carefully, as challenges like material shortages and geopolitical tensions can significantly impact availability and pricing.

Furthermore, projections indicate that the Printed Circuit Board Assembly Market will see substantial growth, with an expected market size of USD 55.33 billion by 2034. This growth reflects a compound annual growth rate (CAGR) of 3.44%. Understanding these trends will empower global buyers to make informed decisions in an increasingly competitive marketplace. Keeping abreast of market forecasts and supply chain developments will be essential for successful PCB procurement and ensuring the ongoing integration of innovative technologies in their products.

Building Long-Term Supplier Relationships: Tips for Success in PCB Sourcing

Building strong, long-term relationships with suppliers is essential for successful PCB sourcing. To achieve this, global buyers should prioritize clear communication. Establishing a rapport where both parties feel comfortable discussing expectations, challenges, and feedback can lead to more collaborative problem-solving. It’s important to set regular check-ins and updates to ensure that everyone is on the same page, thereby minimizing misunderstandings and fostering a sense of partnership.

Another key aspect is investing in the supplier's growth. Supporting your PCB suppliers with resources or expertise not only helps them improve their capabilities but also reinforces your commitment to the relationship. Consider joint training sessions or workshops that can enhance skills and share knowledge about the latest technologies and trends. This cooperative approach can result in higher quality products and more innovative solutions, giving both sides a competitive edge in the rapidly evolving electronics market.

By focusing on these strategies, global buyers can secure reliable supply chains and enhance their overall sourcing effectiveness.